Scara-Classify Objects on Dynamic Conveyor

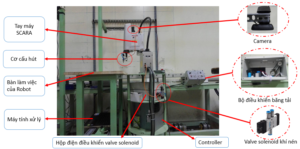

The main task of the equipment is as follows:

- Atmega328: will control the conveyor by PID, read data encoder to gripping the moving objects. Send the encoder pulse data to the computer.

- Computer: is used to collect data from the camera, process images, receive data from Atmega328 and send data to the controller.

- Controller of Robot: receive data from computer, control robot to gripping objects.

Figure 1: Control system structure

Figure 2: Model of control system

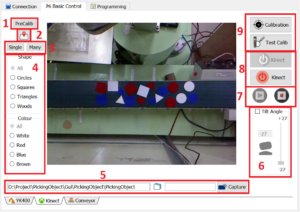

Figure 3: Software control interface

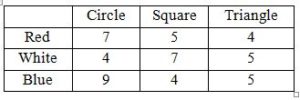

Sort by color and shape:

Objects, numbers and colors:

Working conditions:

- Maximum conveyor speed is 5cm/s.

- The object is randomly selected and dropped regardless of the order and direction of rotation.

- Light reference is not changed.

Output result as following:

- Total object: 50

- Missing object: 0

- The number of objects is misclassified: 0

- Number of objects in the wrong direction: 0

- Total time to execute: < 2 min.

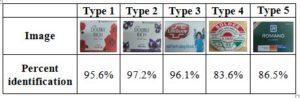

Classification based on the characteristics of the object:

Watch video: